Regardless of how high quality your water softener system is, and even if you maintain it exactly as is recommended, there is a chance it will develop a leak. Fortunately, diagnosing a leak in your system is simple.

Here is what to look for if you’re asking, “Why is my water softener leaking?” and what to do about it.

Signs You Have a Leak

The most obvious sign of a leak is puddling. Even a few drops of water around your system indicate that water is escaping.

If the puddling grows consistently, you have an active leak. If it only grows when you use the system, it is a leak caused by pressure.

A lack of water pressure is another sign you might have a leak. A third is a degradation of the quality of water in your system.

If any of these symptoms exist, you need to start troubleshooting your system to identify where your problem resides, as it will only worsen with time.

Leaking Hoses

A leaking hose is a common type of water system leak. The reasons a hose might leak can include a hairline fracture, puncture, rotten hose, or loose connection point. Inspect your system’s hoses and look for signs of moisture or puddling beneath a hose.

If you locate a leaking hose, try and figure out why it is leaking. Check the connection points above the leak, run the system to see if you have a fractured or punctured hose, and handle the hose gently to see if there are weak spots, which indicates rotting.

Depending on what you find, you have a few options:

- Tighten your connection points

- Use a repair kit, particularly if the leak is small and the integrity of the hose is obvious

- Replace the hose or the connecting equipment

Brine Tank Puncture

A brine tank puncture is also an easily identified leak. Look on the side and at the bottom of the tank for moisture and puddling. Brine tanks failing will usually happen because a salt bridge causes a weakness in the tank wall or at a seam. Pressure from the system can force a leak to develop or worsen one that already exists.

The fixes for a punctured brine tank depend on how serious the puncture is. If the rupture in the tank is minor, with almost no water leaking, use epoxy to seal the hole. If the rupture is at a seam or a portion of the tank wall is weakened, your best bet is to replace the tank.

Only use the recommended type and amount of softener salts to prevent the tank from being corroded to the point of leaking. If you think a salt bridge has developed, use warm water to help break it up.

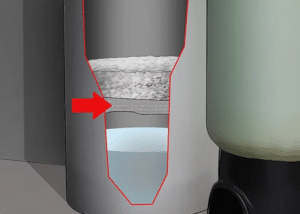

Leaky Resin Tank

The resin tank on your system can also develop a leak or crack. Look for moisture pooling on the external surface of the tank. If you see any, check your warranty first, as you might be able to get a replacement from the manufacturer.

If your warranty is no longer valid, clean your tank and let it dry. Then, coat the puncture or crack with waterproof epoxy. Let it dry and bring your system back up online. If the leak persists after you have applied epoxy, replace the tank.

Malfunctioning Safety Float

Another source of a water softener system leak will be obvious from an overflowing brine tank. In that case, the most likely culprit is a faulty safety float cap. The float cap is supposed to activate a shut-off of the water intake valve if the water in the tank rises above the safety mark. Sometimes, however, the float malfunctions.

A few things can cause a float to malfunction.

First, it can lose its buoyancy due to age. If that happens, the float needs replacing.

Second, the float cap system might have corrosion that impedes the float from moving up and down. Remove the cap apparatus from the tank and run it under hot water. You can also carefully wipe the apparatus to remove any obvious corrosion buildup.

Third, the ball beneath the cap might not be moving freely. If this happens, the ball is probably faulty.

Finally, the float cap itself might not work right. Notice if when the water level should be raising the float, the cap lags just underneath the water. If it is submerged at all, replace it.

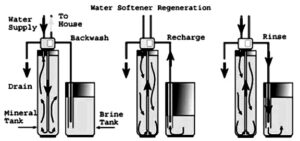

Clogged or Malfunctioning Drain Line

Another major cause of a water softener system leak is a drain line with a bad seal, poor connection, or rupture. Clogs can cause all three problems, though, in the case of a bad seal, degradation due to age is more likely. The best way to find a drain line leak is to find where it drops from the drain line to the floor and then follow the moisture to its source.

If you have a drain line leak, you should replace the drain line. If that is above your skill set, and it can be tricky to install properly, call your service company to have an expert replace the line. The same logic applies if your drain line has a blockage. You can try simple steps, like flushing it with warm water, but the likely outcome will be replacing the line.

Overflowing Brine Tank

As mentioned above, an overflowing brine tank can be caused by a faulty safety float, but that is not the only way a brine tank can reach the overflow stage. Here are a few other ways your brine tank can exceed its limit:

- Salt clog

- Improperly set float cap

- Clog in the drain line

- Brine tank valve blockage

- Blocked injector

- Bad spacers

To troubleshoot a brine tank issue:

- Inspect the valves, drain line, and injector, looking for obvious blockages or corrosion

- Be on the lookout for broken components

- For blocked components, clean them, but if the components are broken, replace them

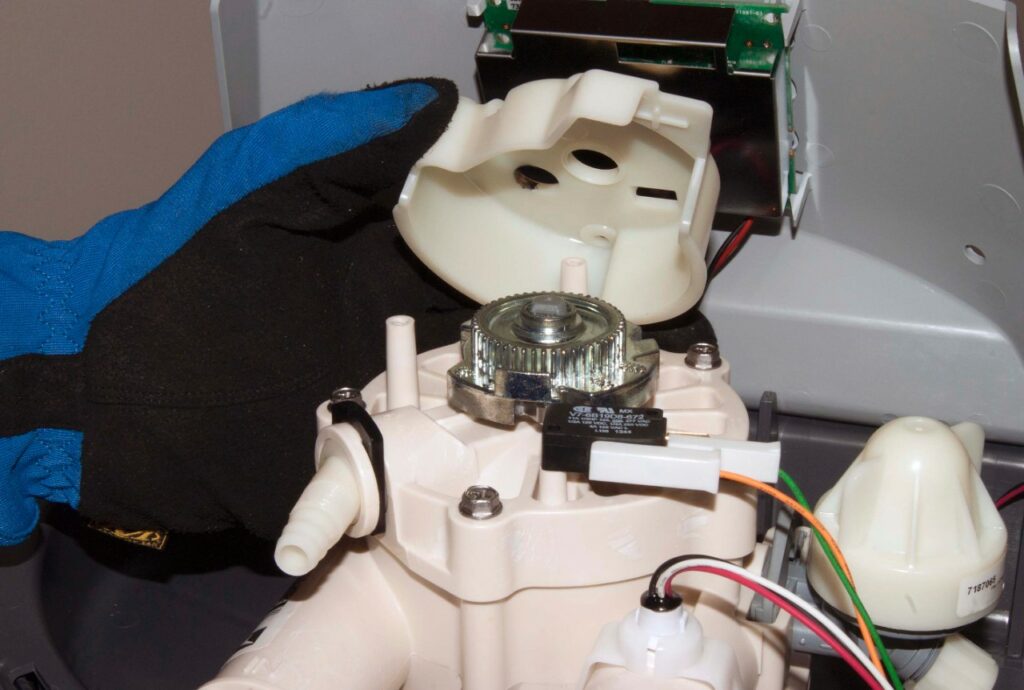

Bad Seals in the Rotor Valve

A leak on the top of your softener system is likely a rotor valve that has gone bad. Rotor valves can wear out, rot, and even break if pressure is an issue with your system. Look for cracks in the seals and the valve casing. With a faulty rotor valve, you can try cleaning it, but the issue usually requires replacement.

Damaged O-Rings in the Bypass

Your system has a bypass valve that lets you terminate water inflow into your system without disrupting your home’s main water supply. Occasionally, the bypass valve will develop leaks because of O-rings that degrade over time.

The degradation can occur because your O-rings dry or wear out. Additionally, mineral deposits from the main water source can build up and create gaps in the O-ring seal.

Dry O-rings need moistening with a manufacturer-recommended silicone-based lubricant. Make sure you follow all manufacturer recommendations, as not doing so can terminate any warranties you have on your system. Additionally, do not use petroleum-based lubricants as that can add to the decomposition of the O-ring further.

Damaged O-rings need to be replaced. If you are not familiar with the bypass valve, it is best to get your system serviced rather than try to do the replacement yourself.

Inspect, Troubleshoot, and Choose Your Solution

If you’re wondering, “Why is my water softener leaking?”, fortunately, for most leaks, the challenge you will face is figuring out what part of the water softener system is leaking. By methodically troubleshooting each component, you can usually figure out quickly what is leaking and how to fix it.